Tanabe Farm was established in 1991 by the Japanese farm owner,

Masahiro Tanabe,

at an elevation of approximately 300 meters in Ecuador,

one of the world's largest banana exporting countries.

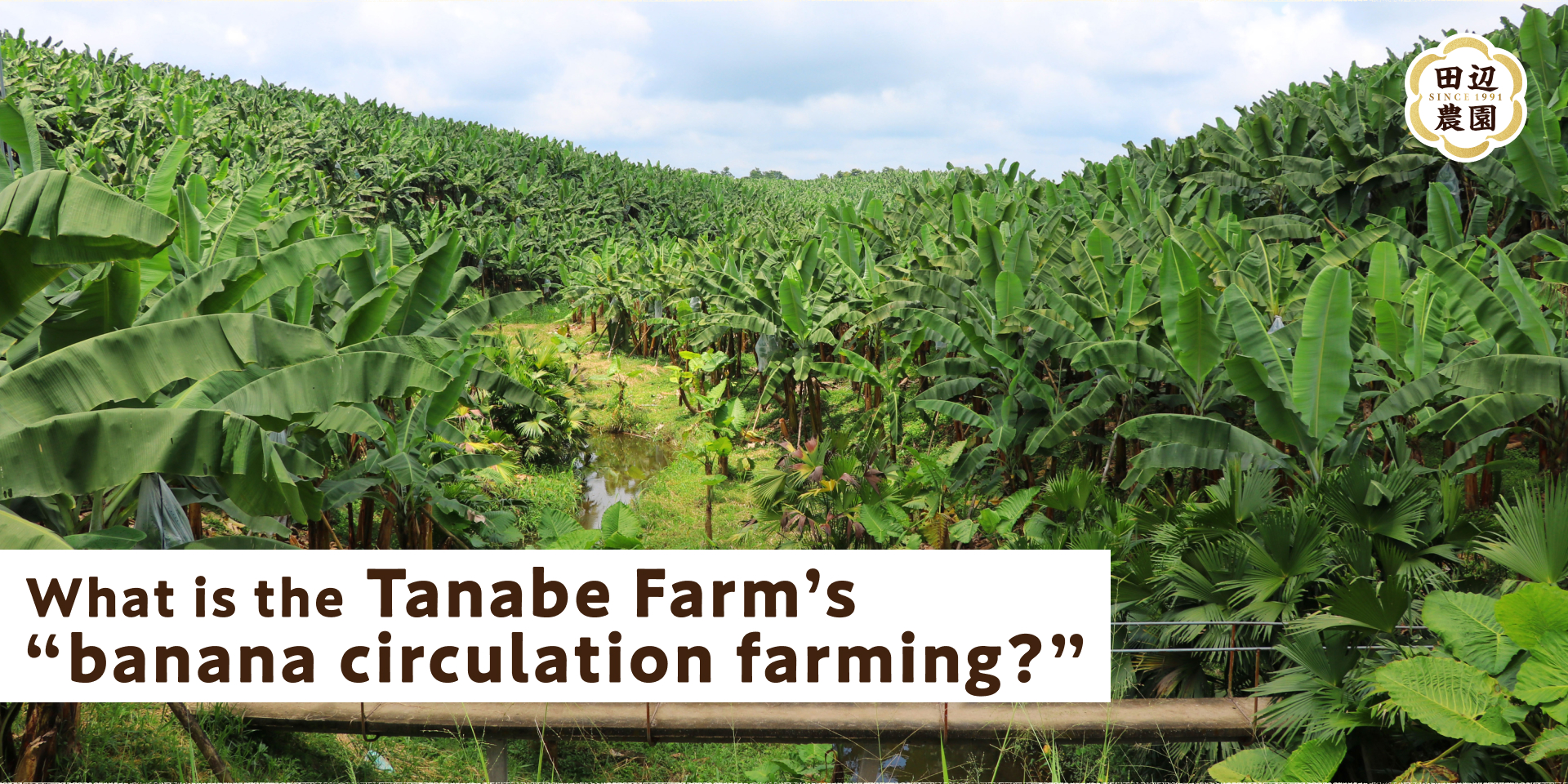

Bananas are grown in an environment that is as natural as possible,

with the natural terrain utilized as it is.

It is more like a "banana forest" on the equator than a banana field.

The landscape can be described as a "banana paradise."

The forest has now grown to approximately 520 hectares,

or about 110 times the size of the Tokyo Dome.

About 500 Ecuadorians from the neighborhood are working

at the vast farm to grow healthy bananas with

smiles on their faces.

The ideal natural environment is maintained through painstaking human intervention.

Based on this "satoyama" concept of Japan,

Tanabe Farm practices a unique organic, recycling-based agriculture,

which can be called the "Tanabe method."

Welcome to the banana forest of Tanabe Farm

From the distant land of Ecuador, about 15,000 km from Japan,

we bring delicious bananas grown with great care to the tables of Japanese consumers.

Tanabe Farm is committed to "soil" and "water."

At Tanabe Farm, banana cultivation begins with preparation of soil.

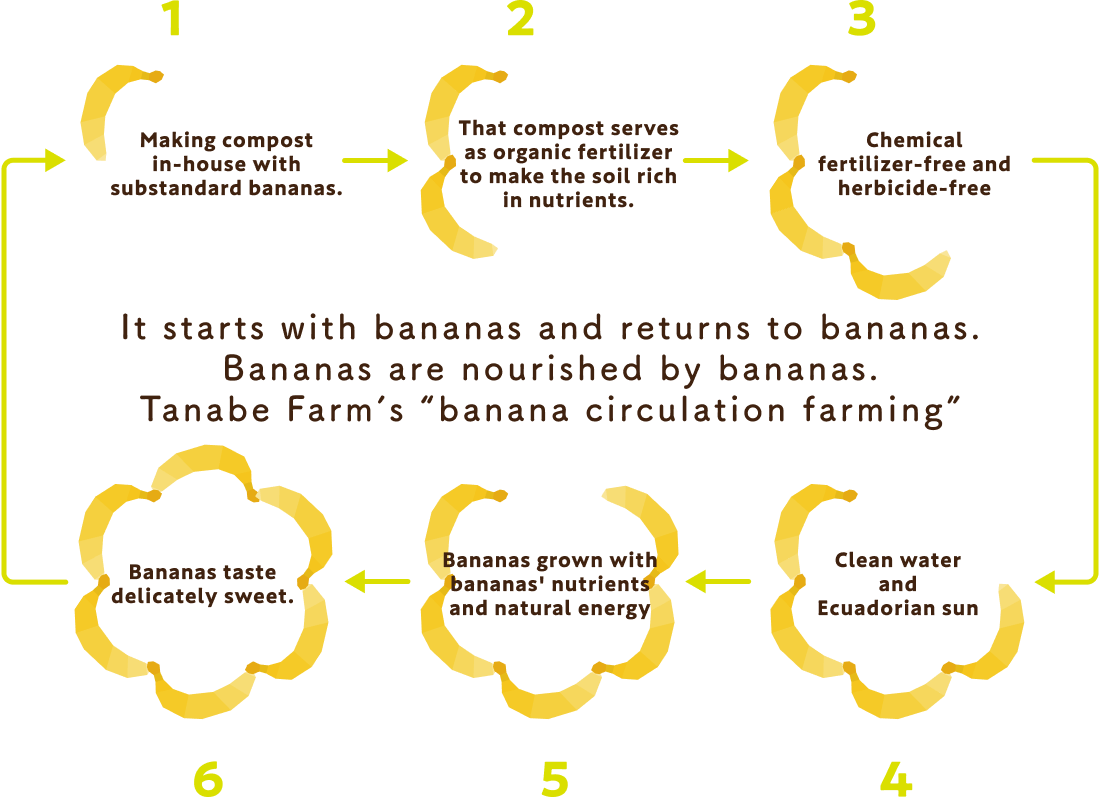

We do not rely on chemical fertilizers and do not use any herbicides.

We start with the preparation of soil by making compost in-house

and introducing plenty of organic fertilizer into soil.

The main ingredient of the compost is substandard bananas.

Bananas that would normally be discarded are not wasted,

but instead are fermented using a unique method and

returned to the soil as organic fertilizer.

In other words, bananas are nourished by the bananas otherwise wasted.

This is the Tanabe Farm’s "banana circulation farming",

a method in which substandard bananas and inedible parts are reintroduced

to banana production.

The recycling of bananas adds richness to their flavor

and imparts sublime sweetness.

Water is another essential element for banana cultivation.

The water used for bananas must be clean enough for human consumption.

Tanabe Farm dug wells and pumps up groundwater to secure clean water,

and even built a dam that utilizes the natural flow

of water to ensure a stable supply of water.

The nourishing soil, clean water,

and the equatorial Ecuadorian sun allow for the growth of

delicious bananas packed

with nature's energy.

-

-

Out-of-spec bananas that would normally be discarded are effectively utilized as raw materials for homemade compost. We return the blessings of the forest to the forest. We value the cycles of nature above all else.

-

Tanabe Farm has four compost sites. There are a total of four types of organic fertilizers made by a unique fermentation process. Each of those fertilizers is used appropriately depending on growing conditions of bananas.

-

The homemade organic fertilizers include liquid fertilizers. In order to preserve a condition as close to nature as possible, we are continuing to study compost production itself.

-

-

-

Bananas are nourished by bananas. Tanabe Farm’s philosophy of banana cultivation is to first prepare nutrient-rich soil.

-

One major difference between Tanabe Farm, which uses no chemical fertilizers or herbicides, and typical banana farms is the presence of lush undergrowth. Bananas also form a symbiotic part of the forest flora.

-

Grown in nutrient-rich soil, banana leaves at Tanabe Farm are lush, very large, and full of vitality. The leaves grow bananas by converting sunlight into energy through photosynthesis.

-

-

-

Ecuador has a rainy season and a dry season. To ensure a stable water supply even during the dry season, Tanabe Farm has built an irrigation dam that utilizes natural water veins and water flow.

-

Tanabe Farm's banana forest has waterways running throughout its natural terrain, with clear water flowing through them.

-

Well water drawn from deep underground is filtered with activated carbon and sterilized with ozone before being used to wash bananas. The treated water is clean enough for human consumption.

-

-

-

Tanabe Farm has 60 hectares of bamboo groves to protect nature. Bamboo cut from this bamboo grove is used as supports for growing bananas.

-

Although it looks like a tree, banana is technically the world’s largest grass. Bamboo poles are essential to support the weight of banana fruit, which can grow up to 30-45 kg.

-

To support banana trees, plastic strings are commonly used in banana fields. "We want to eliminate as many unnecessary artifacts from the forest as possible." This is the reason why we grow bamboo groves and cut out bamboo.

-

-

[Comparison with a typical banana farm]

-

Chemical fertilizers are used to efficiently produce large quantities of bananas. (White grains are chemical fertilizers)

-

Only banana trees are neatly lined up on the thoroughly cleared and herbicide-sprayed land, with almost no underbrush.

-

To support the load of bananas, strong plastic strings run throughout the farm and are left in the field after harvesting.

-

-

-

The presence of useful microorganisms is essential for the soil in which bananas grow healthy and vigorous. Tanabe Farm has a dedicated laboratory for cultivating microorganisms.

-

Tanabe Farm is particular about water and always requires that the water used for bananas be of good enough quality for human consumption. (The photo shows the latest ozone sterilization equipment.)

-

Groundwater is pumped up and stored in tanks so that plenty of clean water is available whenever needed,even during the dry season. A state-of-the-art water storage system is also installed.

-

-

In hope of producing safe and delicious bananas everyone can enjoy with peace of mind,

Tanabe Farm strives to give full consideration to preserving the natural environment,

protect the beautiful "banana forest," and continue sustainable agriculture.Our daily efforts are also recognized under the most demanding global standards for sustainability,

and have earned us two international certifications: GLOBAL G.A.P. and Rainforest Alliance.-

GLOBAL G.A.P

An internationally recognized certification program.

Its purpose is to connect agricultural producers and sellers for the production and trade of safe food,

the protection of scarce resources, and the building of a sustainable future.It is an international certification that requires sustainable agricultural practice

simultaneously achieving

(1) safety for consumers (food safety), (2) safety for workers (labor safety),

and (3) preservation of the natural environment (environmental preservation),

at an agricultural production site. -

RAINFOREST ALLIANCE

The Rainforest Alliance is an international non-profit organization

that combines the interests of companies,

farmers and foresters, with a view to making responsible business practices the new norm.

Established to conduct forest conservation activities in the rainforests of Central America,

the Alliance now provides training and certification in sustainable agriculture

in over 60 countries worldwide.The expansion of agricultural lands accounts for 70% of the reasons for deforestation

and is the biggest threat to tropical rainforests.

Farms are causing soil erosion, water pollution, and destruction of wildlife habitats.

Tanabe Farm has obtained the Rainforest Alliance certification

in order to promote environmental conservation efforts

and contribute to a sustainable society, together with customers.

-

Tanabe Farm's logo represents

the company's commitment to sustainable banana farm operation

as well as its wish for the realization of a sustainable society

where people and nature coexist in harmony.

-

As brown banana flower petals turn outward and young green fruit inside begins to appear, bananas will soon be bearing fruit. At this point, the blossoms are carefully covered with bags.

-

The thin plastic bags with air holes protect the precious bananas from birds and insects. Bananas grow safely in the bags.

-

If the undergrowth is allowed to grow unchecked, the weeds will take nutrients from the soil. At appropriate intervals, the undergrowth is also cut by hand.

-

When the banana fruit reaches the desired size and ripeness, it is ready for harvest. Working in pairs, we reap bananas from the base of the banana stem, entirely by hand.

-

A large bunch of bananas can grow up to almost 45 kg. The bananas are carried on a special mat to the cableway base so as not to bruise them. It requires hard physical work.

-

The harvested bananas are hung from cables strung across the farm, and then pulled by workers to the packing house.

-

Bananas are hooked up to the cables and transported to the nearest one of the four packing houses in the farm. The cable is one of the few man-made objects in the forest.

-

Upon arrival at the packing house, the bananas are first rigorously checked for conditions and ripeness by our quality control specialists.

-

After quality inspection, bananas are first washed with water that is clean enough for human consumption. The water has been filtered through activated carbon and sterilized by ozone.

-

Once the bunches of bananas are split into small bunches, a vigorous shower is used for secondary washing. The bananas are cleaned further in a pool of cold water.

-

Finally, each banana is carefully washed by hand, while being inspected for quality. This thorough sanitation management is only possible by the Japanese farm.

-

Each bunch is covered with a film sheet to prevent spoilage from the cut of the stem, which is vulnerable to damage.

-

Once they are neatly covered with the film and affixed with the Tanabe Farm sticker, they are ready for shipment. Delicate quality control is also unique to the Japanese farm.

-

All of bananas harvested at Tanabe Farm are sent to Japan. The bananas are shipped in large reefer containers almost daily from the four packing houses.

-

Tanabe Farm's bananas, nourished by bananas, are natural and delicately sweet. We hope you enjoy this deliciousness.