Frescana is a combination of the Spanish word for fresh, fresco, and ANA, and we at ANA Foods are proud to have it as part of our product lineup. These bananas are harvested from a specially chosen farm on Mindanao island in the Philippines.

We give the utmost attention to quality management, with staff visiting the site frequently to ensure that our bananas are safely delivered from the farm to our customers.

Our Two Commitments

Our Two Commitments

-

Putting Our Passion

into Every Single BananaEach and every banana is lovingly cultivated at the farm with the utmost attention paid to quality management, and everyone associated with the bananas, from importing to processing and sales, handles the product with real care.

-

Knowing Where

Our Bananas come fromWe oversee all aspects of the frescana product to create a single, unbroken chain from cultivation in the Philippines to distribution within Japan, from providing farming instructions at the farm up to importing the bananas into Japan and processing and distributing them.

Our Bananas' Journey

We Deliver safe, trustworthy bananas from the farm to our customers through a single unbroken chain.

Bananas are harvested when they are still green, and at this point are still too hard to eat.

So why are the bananas that we see in stores yellow?

To find out, let's follow the road that our own-brand frescana bananas travel along—from the island of Mindanao in the Philippines

where they are harvested up to the point they are displayed in stores.

Up to Harvest

-

1. Creating a nursery bed

To cultivate bananas, the first thing to do is create a nursery bed. The bananas are grown here until they reach a certain size.

-

2. Planting

Seedlings are planted one by one a set distance apart from each other.

-

3. Covering with a bag

Each bunch is covered with a bag in order to prevent damage by pests and encourage growth, and this is also all done by hand.

-

4. Measuring

The thickness of the bananas is checked using a measuring instrument called a caliper. If they pass the requirements, they are ready to be harvested.

-

5. Harvesting

The bananas are harvested by pairs of workers, with one cutting them off and the other taking them down. Each harvested bunch weighs about 30 to 40 kilograms.

-

6. Measuring (thickness/ripeness)

After harvest, each bunch is re-checked for thickness and quality, with only those meeting the requirements shipped to Japan.

Cleaning and

Packing

-

1. Dehanding

The bananas are separated into hands, and the whole process is done quickly and carefully so they can be shipped while still fresh.

-

2. Washing & trimming

The bananas are washed thoroughly and the crown (stem end) trimmed. Bruised or otherwise spoiled bananas are again removed at this point in the process.

-

3. Measuring

(separation by grade)The trimmed bananas are weighed to see which grade they fall under, and are separated accordingly.

-

4. Labeling

Frescana stickers are placed only on those bananas that have passed the stringent inspections up to this point.

-

5. Placing into bags

Each cluster is placed into bags and wrapped.

-

6. Second mesuring

A final check is done to see if all the packs comply with weight standards.

-

7. Packing (into boxes)

The bananas are placed carefully into boxes for shipment, one hand at a time. This is something that requires experience to do.

From Shipment to

Arrival in Japan

-

1. Third measuring

The weight is checked again, and the date and code number of the person in charge are filled in to ensure the bananas are shipped responsibly.

-

2. Inspection & shipment

Sampling is conducted at regular intervals to ensure the bananas are of a consistent quality.

-

3. Arrival at the port

The ship departs from the Philippines and arrives in Japan after about five days.

-

4. Unloading

Since the bananas remain in pallets, they can be unloaded quickly without any spoilage or bruising.

-

5. Land transport

The bananas are transported from the port to the ripening chamber within the processing plant.

-

6. Arrival at the port

The bananas are still a vivid green color upon arrival at the chamber.

Ripening & Delivery to Stores

-

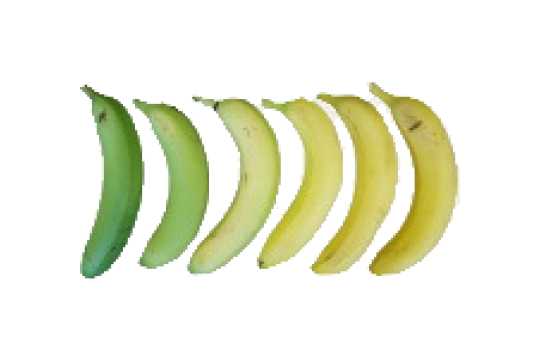

1. Placing into ripening

chamberThe bananas are kept in the pallets and placed into the ripening chamber, and they turn a yellow color after five to seven days.

-

2. Coloring

The entire ripening chamber is centrally controlled by computer to make sure all the bananas turn an even yellow color.

-

3. Ripening

The bananas are ripened in accordance with their condition by adjusting the temperature and humidity.

-

4. Separating by color

The bananas are ripened in accordance with the colors designated by mass retailers.

-

5. Quality Inspection

Only bananas passing the final quality inspection are distributed across Japan.

-

6. Delivery to stores

The ready-to-eat bananas are put on display at stores—a familiar sight to us all!